Our company always looks at sustainability while developing any products. Few details of the same:

- Creating packaging concept enabling customers to avoid wood & plastic packaging:

We have worked closely with customers to move completely from wooden packaging to metal packaging for export of car parts. As steel pallets are recyclable and a very good alternative to wood, we have been developing innovative designs to cut the wood intake.

- Increasing pack quantity per pallet reducing transport & shipping cost:

We work on innovative designs with which the customer is able to fit more parts in same export container. In a recent project, our company was able to increase the pack quantity by 33% and reducing the export container requirements by close to 25% which not only has a positive impact on customer project cost but also reduction of pollution as a smaller number of racks will be used.

- Reducing materials:

We also work closely with customers to reduce the material intake and use more easily recyclable materials in our products reducing any negative impact on the customer.

- Modification of old Packaging Material:

We also work with customers to modify old products such that they can be re-used for new designs instead of scrapping. Over the last one year, we have worked closely with customers in various modification projects.

- Returnable Packaging:

We have helped many customers to move to returnable packaging from one-way packaging. The car parts move in our rack to the end location, once the part is removed, the empty rack is shipped back. By doing this, we are able to reduce the waste generation drastically.

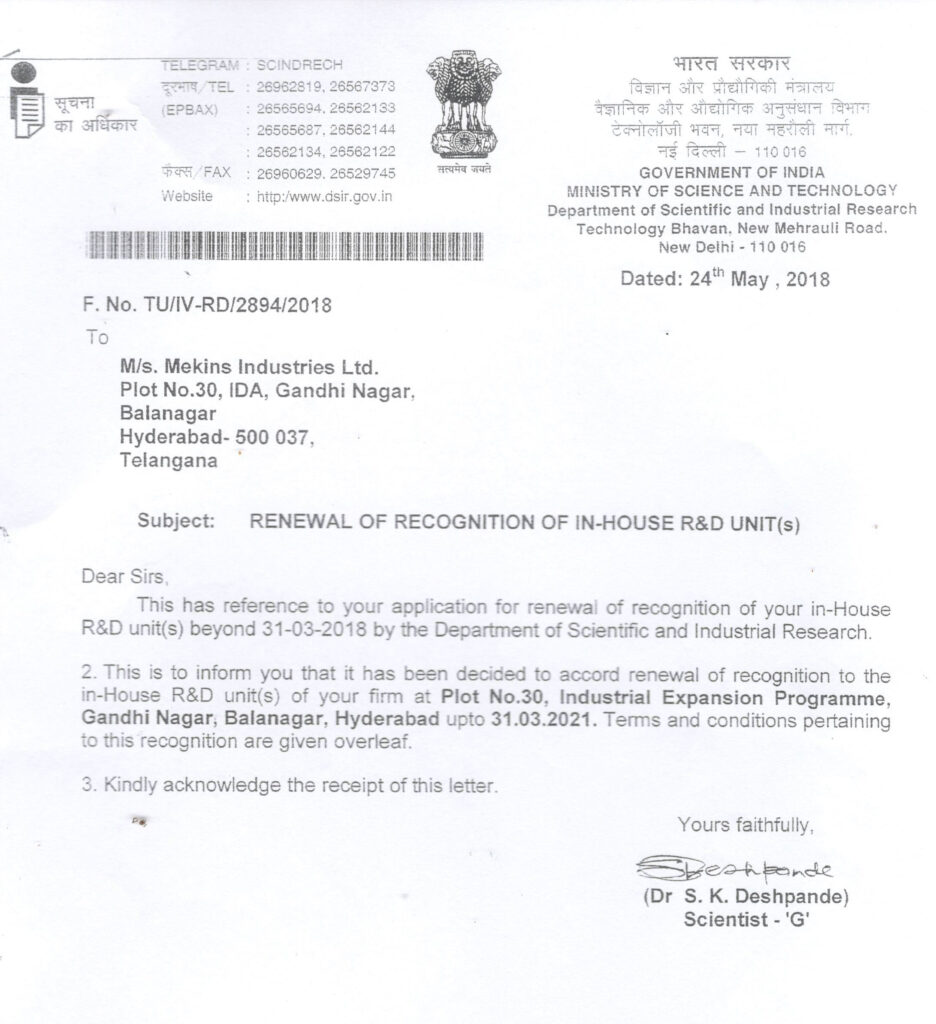

Our company is recognised by Department of Scientific and Industrial Research (DSIR).